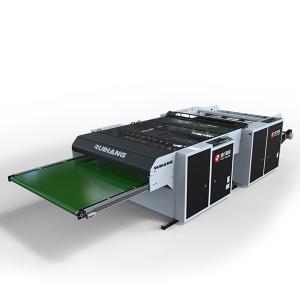

FFS heavy duty film blowing line Three to five layer FFS repackaging film blowing machine

FFS heavy duty film blown line

Three to five layer FFS repackaging blown film machine

Equipment Introduction:

FFS three-to-five layer co-extrusion film blowing machine adopts automatic film thickness control system, automatic air ring, IBC internal cooling control, PLC touch screen control automatic winder and automatic weighing system technology. It can provide a variety of options in the application of materials, fully reflecting different levels of function. Widely used in packaging Main products (chemical raw materials, food, fertilizer), heavy packaging bags, and exported to Europe, Russia, the United States, the Middle East, India, Pakistan, Turkey, Mexico South American countries, Yemen and other countries, and received praise from customers. It also has close cooperation with China's famous packaging leaders

Performance characteristics of this unit:

Adopt upward traction rotating device, supporting EPC correction system; Solve the phenomenon of large and small heads and ruffles, and reduce the frequency of equipment maintenance;

2. The equipment adopts IBC internal cooling control system to improve output, film yield and shrinkage performance;

3. The automatic winding machine is adopted to reduce the labor intensity of the operator and reduce the labor cost, and the automatic winding device is equipped with a boom device to facilitate the lifting of the gas shaft;

4. The winding adopts 3 sets of automatic tension control system, the tension is constant, and the winding adopts servo motor drive;

5. The barrel screw adopts high-speed, high-plasticizing screw, good plasticization and high output;

6. Using Taiwan technology high-efficiency double duct air ring, stable foam, large air volume, fast cooling of membrane bubble;

7. Adopt the online recycling system of offcuts to realize the online utilization of waste film;

8. High-quality squirrel cage bubble stabilizer design, the bubble stabilizer is designed for electric lifting structure;

9. The opening and closing of the herringbone board adopts electric adjustment mode, electric opening and closing, and electric lifting;

10. The fan adopts a large air volume noise reduction blower, frequency conversion speed regulation, more energy-saving;

11. The secondary hard tooth surface gearbox adopts the national standard type, the reducer bearing is enlarged, and the gearbox adopts the direct connection form; The performance of the reducer is more stable, and there is no oil leakage and other phenomena;

12. The main motor adopts permanent magnet servo type motor and high torque output motor;

13. Adopt Taiwan technology new rapid hydraulic screen change system, the replacement of the net is more convenient and sealed; Set a precision pressure sensor before the extruder is changed to display the pressure and temperature;

14. The traction and coiling transmission adopts the RV reducer direct connection type, which avoids the quality of the film from being affected by oil pollution;

15. The winding adopts inflatable winding shaft, which is more convenient and fast to change the wind; Reduce wear on the paper core;

16. The shaft heads at both ends of the guide roller in the equipment are all anti-rust treatment;

| Technical Specifications |

| Madel Name | FFS heavy duty film blown line Three to five layer FFS repackaging blown film machine |

| Final product | HDPE, LDPE, LLDPE, EVA |

| Application | Heavy packaging film |

| Material used | HDPE/LLDPE/LDPE/MLDPE/POE |

| Output range | 100~400 kg/h |

| Film layer | Three/five layer |

| Screw diameter | Φ45/Φ50/Φ55/Φ60/Φ65/Φ70mm |

| Screw L/D | 30:1,32:1 |

| Screw Material | 38CrMoAI |

| Width | 200mm-700mm (customized according to customer's packaging) |

| Thickness | 0.03~0.15mm |

| Optional Devices | Online wind ring, online thickness measurement, IBC internal cooling, upper traction rotation, automatic correction, double section and double receiving, online recovery system, central feeding system |

| Delivery Time | 60-120 days |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

| Dimensions |

Screw L/D:30:1

Max output: 400kg/hr

horizon level: ±180

Winding speed: 45-120m/min

Max layer flat width: 3000mm

Screw diameter: 70mm+95mm+70mm

Main motor power:55kw,90kw,55kw

3CMJ95-3000A

Screw L/D: 30:1

Max output: 300kg/hr

horizon level: ±180

Winding speed: 45-120m/min

Max layer flat width: 2500mm

Screw diameter: 60mm+70mm+60mm

Main motor power: 22kw,37kw,22kw

3CMJ70-2000A

Screw L/D: 30:1

Output: 140kg/hr

horizon level: ±180

Winding speed: 45-120m/min

Max layer flat width: 1500mm

Screw diameter: 45mm+55mm+45mm

Main motor power: 18.5kw,30kw,18.5kw

3CMJ55-1800A

Screw L/D: 30:1

Output: 200kg/hr

horizon level: ±180

Winding speed: 45-120m/min

Max layer flat width: 1800mm

Screw diameter: 50mm+60mm+50mm

Main motor power: 22kw, 37kw, 22kw

3CMJ60-1300A

| Applications |

CATEGORIES

CONTACT US

Contact: Karen

Phone: +86-15127982956

Tel: +86-15127982956

Email: ruihang.sale@gmail.com

Add: Ningjin County, Xingtai City, Hebei Province,China